Optimal Timing for Epdm Roof Inspections

Epdm roof inspections are essential for maintaining roof integrity and preventing costly repairs. The timing of inspections can influence their effectiveness and the detection of potential issues. Understanding the optimal periods for inspection ensures roofs are examined when conditions are most favorable for accurate assessment.

Ideal for assessing winter damage and preparing for the warmer months.

Suitable for checking for heat-related damage and ensuring proper waterproofing.

Prepares the roof for winter by identifying vulnerabilities before cold weather sets in.

Ways to make Epdm Roof Inspections work in tight or awkward layouts.

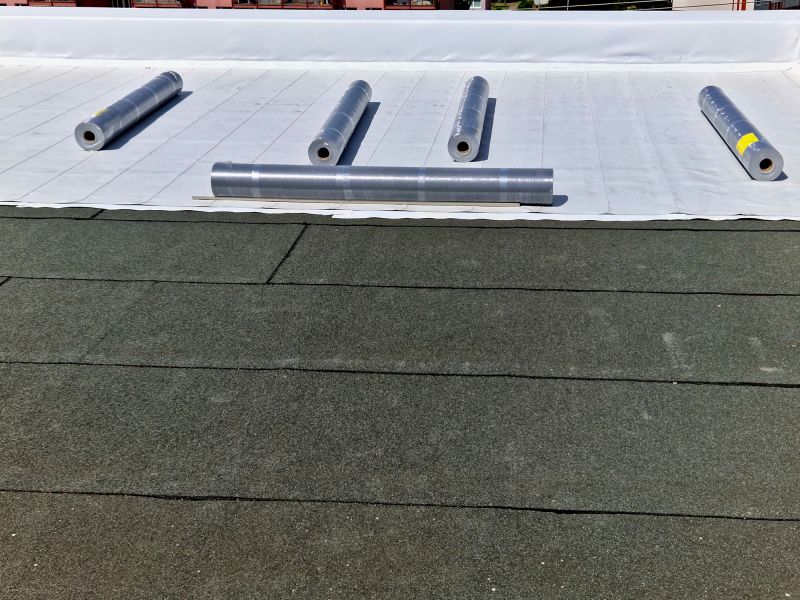

Popular materials for Epdm Roof Inspections and why they hold up over time.

Simple add-ons that improve Epdm Roof Inspections without blowing the budget.

High-end options that actually feel worth it for Epdm Roof Inspections.

Finishes and colors that play nicely with Epdm Roof Inspections.

The optimal times are during spring, fall, and early summer when weather conditions are mild, allowing for thorough inspections without interference from extreme heat or cold.

Mild weather provides better access and visibility, reducing the risk of missed issues and ensuring accurate assessments.

Typically, twice a year is recommended, ideally in spring and fall, to identify and address issues promptly.

Winter inspections are possible but may be less effective due to snow, ice, and cold temperatures that can obscure damage or complicate access.

| Season | Recommended Inspection Time |

|---|---|

| Spring | After winter weather, before summer heat |

| Summer | Early summer for maintenance checks |

| Fall | Before winter weather sets in |

| Winter | In mild conditions, if necessary |

| Post-storm | Immediately after severe weather events |

Epdm roof inspections are a vital aspect of maintaining roofing systems, offering early detection of issues such as membrane punctures, seam separations, or UV damage. Regular inspections can extend roof lifespan, reduce repair costs, and ensure waterproof integrity. Studies indicate that proactive inspections can identify problems before leaks develop, saving property owners significant expenses over time.

Utilizes specialized equipment to detect underlying issues not visible to the naked eye.

Includes checking seams, flashing, and membrane condition for signs of wear or damage.

Identifies cracks, blistering, punctures, and seam separations during inspections.

Ensures minor issues are addressed promptly to prevent further deterioration.

Little measurements that prevent headaches on Epdm Roof Inspections day.

A 60-second routine that keeps Epdm Roof Inspections looking new.

A frequent mistake in Epdm Roof Inspections and how to dodge it.

Small tweaks to make Epdm Roof Inspections safer and easier to use.

Proper timing and regular inspections are critical for maintaining the durability of Epdm roofing systems. By scheduling inspections during optimal seasons, property owners can ensure early detection of issues, reducing the likelihood of leaks and structural damage. Consistent monitoring supports the longevity and performance of the roof, ultimately protecting the building’s interior and contents.